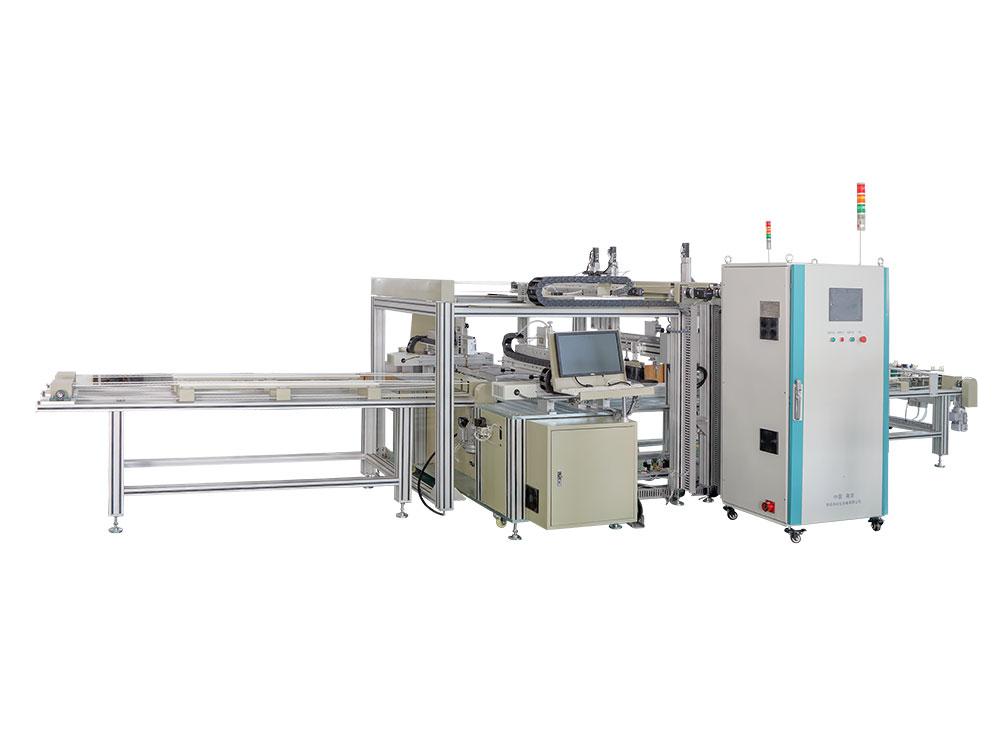

Automotive Rear View Mirror Production Line

The automotive rear view mirror production line is used for cutting two large pieces of glass into specially shaped pieces, such as automotive rear view mirrors. It is suitable for mass production of automobile and motorcycle mirrors alike.

Production line operation Technical parameters| A. Reformed pieces: the glass is divided into two pieces after hot bending | |

| Maximum glass size | 230×330mm~370×470mm |

| Glass thickness | 1-3mm |

| Cutting precision | ±1.0mm |

| B. Molding cutting: two separate cutting systems to cut | |

| Control system | Computer control+ I/O CNC software+ CNC special digital software |

| Cutting precision (mm) | |

Note: The glass size and input power supply voltage level can be customized

Features

1. The automotive mirror production line features two groups of rotary molding cutting platforms. These platforms use industrial control computers with CNC special cutting software, which allows two sets of glass to be cut simultaneously using computer programming and control. The glass piece shape can be the same or different.

2. Four tri-rod cylinder s position the glass in a precise manner in 4 different directions, as well as carry out grabbing and shifting in order to prevent glass bumping or scratching.

3. With multiple protective devices, the production line will detect and automatically sound an alarm in the event of any operation abnormalities, thus ensuring normal equipment operation.

4. The main electrical and pneumatic components come from Schneider in France and Yaskawa in Japan, thus ensuring the reliable quality and outstanding work stability.

5. The working speed is fast and the work efficiency is extremely high. This ensures a higher production and quality, resulting in an overall reduced labor cost.

Besides the automotive rear view mirror production line, Yetuo offers wide range of glass processing equipment for glass cutting, glass edging, glass washing, etc. Our company has complete equipment to manufacture quality automatic glass machinery for making lots of mirrors and glass.

Advantages

The automotive rear view mirror production line is fully automatic, from raw material glass to the finished automobile mirror (which includes large cutting (separated cutting), chamfering, bending before cleaning the glass, hot bending of the glass, glass coating before cleaning, special shape cutting, chamfering, edge grinding and final cleaning). Specific parts of automation can also be achieved based on specific customer needs.

1. Reduce labor costs: Because the automatic production line requires fewer human operators, labor costs are significantly reduced, while simultaneously increasing profits.

2. Improve product quality: Errors caused by manual operation are reduced, and the amount of products deemed unacceptable is reduced, thus ensuring an improved overall product quality.

3. Reduce energy consumption: With a processing optimization, down time is reduced, which in turn reduces energy consumption.

4. Reduce production area size: Because the amount of down time is reduced, there is less space needed for product storage during different procedure steps.

5. Flexible arrangement: The production line layout can be customized according to customer needs, with either full or partial automation available to choose from.

6. Easy to use: the production line doesn’t change the original processing craft, so operation and maintenance is easy.

Besides the automotive rear view mirror production line, Yetuo offers wide range of glass processing equipment for glass cutting, glass edging, glass washing, etc. Our company has complete equipment to manufacture quality automatic glass machinery for making lots of mirrors and glass.

Nanjing Yetuo Automation Equipment Co.,Ltd.

Add.: Building C2, No.9 Zhongxing Road, Zhongshan Science Park, Liuhe District, Nanjing City, Jiangsu Province, China

Tel.: +86-25-57671235

Fax: +86-25-58395043